Timber Frame Construction

Our Systems

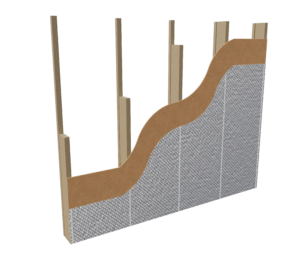

Open Panel Timber Frame

Our open panel timber frame offer is a cost effective, flexible approach to off-site construction. The use of panelised timber frame allows rapid site build, while retaining the flexibility of fitting insulation on site.

Benefits of Open Panel

- Fast on-site construction with predictable programs

- Supported with full thermal engineering service to ensure thermal specifications are met

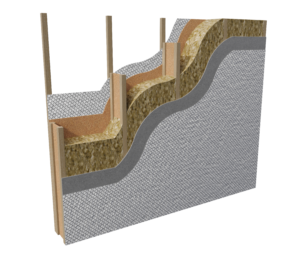

Scottherm Hybrid Panel

Our hybrid panel increases the pre-manufactured element of the wall construction, while still allowing for site inspection and warranty approval. The panel includes factory-fitted PIR insulation to reach the required thermal performance, ready to have membrane and any additional material site-fitted, post inspection.

Benefits of Scottherm

- Factory fitted insulation, increasing system pre-manufactured value (PMV)

- Allows for site inspection

- Reduced on-site labour required

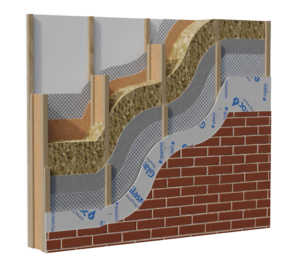

ThermistudTM

ThermistudTM is a closed timber wall panel system designed to support the efficient construction of high-performing homes. The system uses an i-stud construction to deliver high thermal performance with reduced cold bridging.

Benefits of ThermistudTM

- Higher PMV than open / hybrid panel systems

- Bespoke fire testing available

- Q-Mark, BOPAS and NHBC Accepts approved, reducing on-site warranty requirements

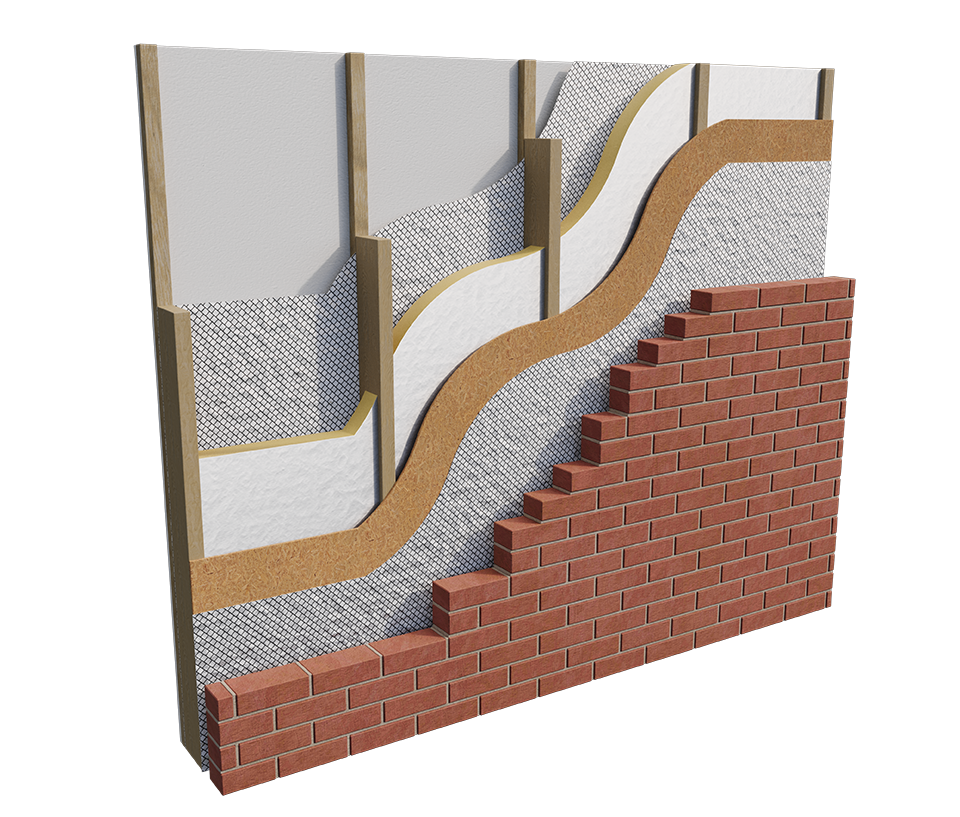

EnveoVent

EnveoVent is a complete ventilated and insulated structural wall system, designed, manufactured and delivered from a single supplier. The system includes internal plasterboard and a choice of external finishes (site fitted). The result is a high-performing, fully tested, guaranteed wall solution.

Benefits of EnveoVent

- Closed panel timber frame system with external cladding and internal board

- Full system warranty including internal and external claddings

Timber frame is a proven off-site construction method that is widely adopted across the UK housing market, accounting for more than 80% of new homes in Scotland and a growing share in England. By manufacturing structural elements in controlled factory conditions, timber frame systems offer consistent quality, reduce on-site health and safety risks, and can help to accelerate build programmes. Using panelised systems minimises weather-related delays, supports predictable project delivery, and helps housing providers meet demand more efficiently.

Alongside programme certainty, timber frame systems deliver measurable performance benefits. Engineered precision and fabric-first design principles ensure strong thermal performance and airtightness, supporting both regulatory compliance and long-term energy savings for occupants. Timber is a renewable material sourced from responsibly managed forests, and building with timber frame can deliver a lower-carbon alternative to traditional masonry construction, as can be seen in our recent study at Salford University.

Home Design

Services for Architects

At Scotframe, we’re dedicated to collaborating with architects nationwide, offering a diverse range of services.

Thermal Engineering Services

Thermal Engineering services schedule for provision of Certificate of Design (Section 6 Energy) / SAP Calculation / Elemental U-Values

Scotframe’s 3D Visualisation Service

Enjoy a tour of your new home with our stunning 3D visualisation service; you’ll feel at home immediately.